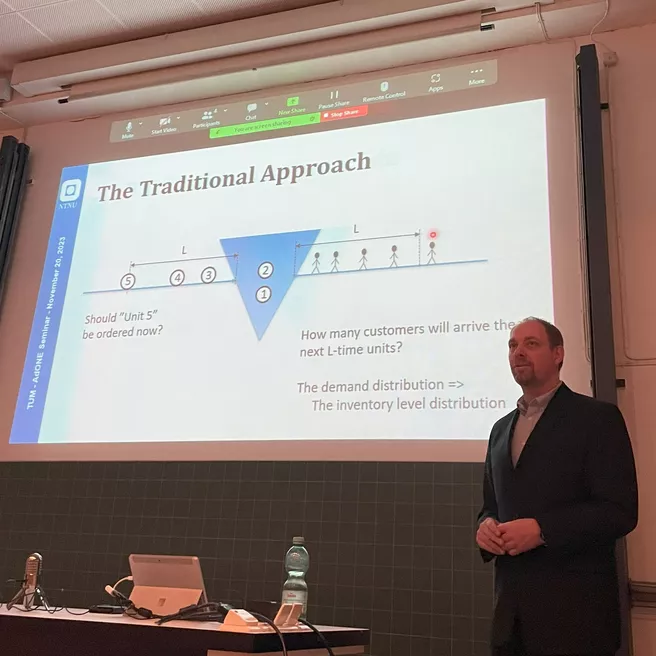

Inventory control is about servicing customers at the lowest cost possible by ordering the right amount to the right place at the right time. Traditional models for inventory control are typically based on predicting and controlling the future inventory level with the aim of minimizing the expected sum of ordering, holding and shortage cost at each location. This makes perfect sense as the two latter costs commonly are proportional to the inventory level and the fact that the distribution of the inventory level “easily” can be determined as the inventory position minus the lead-time demand under the assumption of a constant lead-times and full backordering has helped to solidify this general approach within the field. However, in 1990 Sven Axsäter[1] turned everything on its head when he suggested that one instead should track the units ordered and the demands that they are matched up with. This since there is a cost for the units when they are being moved or stored as well as cost for the demands that arises when there are no units available to satisfy them. Axsäter referred to this method as the “simple solution procedures” and it was later popularized by Muharremoglu and Tsitsiklis[2] under the more descriptive name, the “single-unit decomposition approach”.

This new approach has allowed us to tackle new as well as classic inventory control problems, including problems with stochastic yield[3], expediting[4] and stochastic purchase price[5]. These earlier works will be presented along with new findings for situations where the inventory manager can purchase as well as sell goods at a stochastic price. Moreover, will new heuristics for the classical lost sales problem and stochastic lead-times problem be suggested. This is a reality for many inventory managers but due to the mathematical complexity these assumptions pose with the classical approach they are typically forced to use methods based on the more common assumption of constant lead-times and full backordering to control these systems.

[1] Axsäter, S. (1990). Simple solution procedures for a class of two-echelon inventory problems. Operations research, 38(1), 64-69.

[2] Muharremoglu, A., & Tsitsiklis, J. N. (2008). A single-unit decomposition approach to multiechelon inventory systems. Operations Research, 56(5), 1089-1103.

[3] Berling, P., & Sonntag, D. R. (2022). Inventory control in production–inventory systems with random yield and rework: The unit‐tracking approach. Production and Operations Management, 31(6), 2628-2645.

[4] Berling, P., & Martínez-de-Albéniz, V. (2016). Dynamic speed optimization in supply chains with stochastic demand. Transportation Science, 50(3), 1114-1127

[5] Berling, P., & Martínez-de-Albéniz, V. (2016). Dynamic speed optimization in supply chains with stochastic demand. Transportation Science, 50(3), 1114-1127.